The Direct-to-Film (DTF) method has revolutionized custom apparel, allowing businesses to transfer vibrant designs onto virtually any fabric. For professional garment manufacturers, understanding the precision required at each stage is essential for maximizing the potential of a high-performance digital textile printer.

Step-by-Step Breakdown of the DTF Workflow

Achieving retail-quality results requires a synchronized process between the printer, the consumables, and the finishing equipment.

Digital Design Preparation: Using RIP software (such as CADlink or RIIN), the design is mirrored and processed. This stage is critical for managing ink density and the white underbase layer.

Printing to Film: The DTF textile printer applies the CMYK color layer followed immediately by a white ink layer onto a specialized PET release film.

Adhesive Powder Application: While the ink is still wet, a hot-melt adhesive powder is applied. In industrial setups, an automatic shaker ensures even coating and removes excess powder.

Curing the Transfer: The filmed design passes through a curing oven or tunnel dryer. This melts the powder, creating a durable adhesive bond.

Heat Press Transfer: The cured film is placed on the textile and pressed at approximately 160°C for 15 seconds. Once cooled (or immediately for hot-peel films), the PET carrier is removed, leaving a soft, stretchable print.

Industrial Efficiency with the XF-450Pro

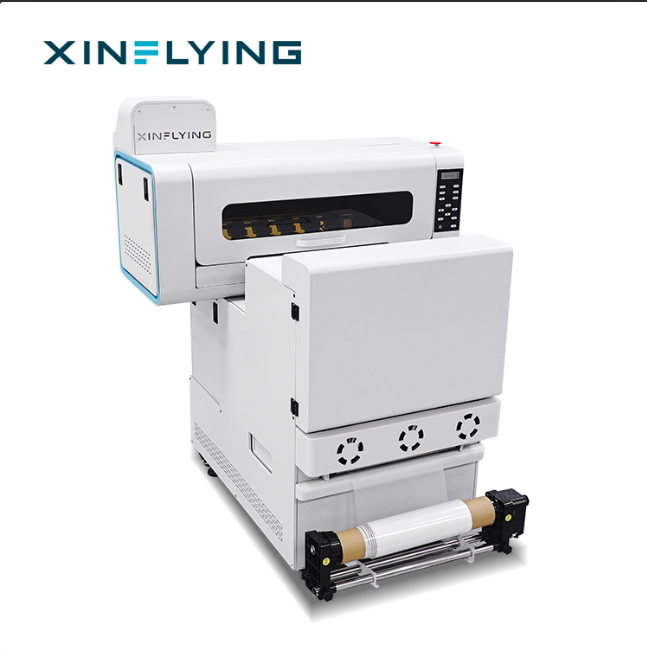

For small-to-medium enterprises looking to optimize this process, Xinflying offers the XF-450Pro A2 All-in-One DTF Printer. This machine is specifically engineered to condense the workflow into a compact footprint without sacrificing industrial speed.

Precise Technical Specifications:

Printhead Technology: Equipped with 2pcs Epson i1600-A1 printheads, offering a longer lifespan and higher resolution than entry-level XP600 models.

Production Speed: Capable of outputting 8m²/h, doubling the efficiency of standard A2 machines.

Precision Engineering: Features a 16.5-inch print width and supports professional RIP software like PrintFactory and MainTop for exacting color accuracy.

Stability: Built with a heavy-duty chassis and an advanced white ink circulation system to prevent nozzle clogging during the printing phase.

By following these key steps and utilizing professional-grade hardware like the XF-450Pro, businesses can ensure their textile production remains both cost-effective and high-quality.