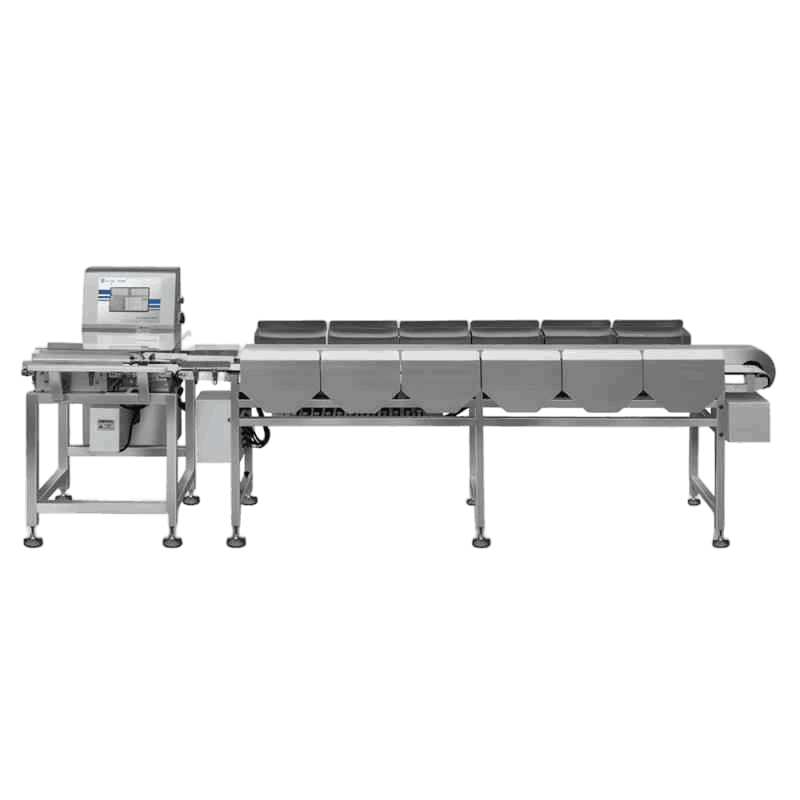

The sorter machine plays a vital role in modern production lines by ensuring that products meet exacting quality and consistency standards. At WEIGHT SORTING, their engineering team has perfected the design of each sorter machine through the integration of advanced weighing technology and intelligent software. By combining high-precision sensors with real-time data processing, every sorter machine under the WEIGHT SORTING brand guarantees superior performance, efficiency, and flexibility. These systems are used across industries such as food processing, packaging, and manufacturing, helping businesses maintain product uniformity and minimize waste.

Precision in Every Gram: Advanced Weighing Performance

At the core of WEIGHT SORTING’s success lies its High-Precision Weighing Technology. Their Weight Sorting Machine incorporates advanced sensors and algorithms that deliver accurate weight measurements for every item that passes through the line. This ensures consistency and optimal portion control, which is critical in industries like seafood, produce, and ready-made meals. The precision of this sorter machine allows operators to detect even the slightest variations, ensuring that each batch meets exact standards before packaging or distribution.

Dynamic Sorting Efficiency Through Real-Time Grading

The Weight Grader Machine from WEIGHT SORTING is engineered for Dynamic Weight Grading, automatically adjusting weight categories in real time. This intelligent feature enhances sorting efficiency while minimizing product giveaway and waste. The sorter machine continuously monitors incoming products, adapting to weight variations instantly. This capability is especially valuable for high-throughput production environments that demand both accuracy and speed without compromising quality.

Seamless Integration and Operator-Friendly Control

WEIGHT SORTING’s Weight Sorter is designed for effortless integration into existing production systems. Its Flexible Integration feature ensures smooth scalability across different product types and production volumes, making it ideal for dynamic manufacturing setups. Additionally, its User-Friendly Interface—a responsive touchscreen control panel—enables operators to monitor performance, fine-tune parameters, and ensure consistent operation with ease. This modern approach reflects WEIGHT SORTING’s dedication to blending precision technology with practical usability.

Conclusion

In a world where accuracy and speed define success, WEIGHT SORTING stands out as a trusted innovator. Their sorter machine solutions combine intelligent algorithms, adaptable design, and user-focused operation to deliver measurable improvements in productivity and quality. By investing in WEIGHT SORTING’s high-performance sorter machine, businesses gain more than just reliable equipment—they gain a partner committed to innovation, precision, and long-term operational excellence.